Introduction:

In today's world, where precision and control are paramount, the demand for custom control cables has seen a significant rise. These cables play a crucial role in various industries, enabling the smooth and efficient operation of complex machinery and systems. From automotive applications to aerospace, robotics to medical equipment, custom control cables offer tailored solutions that meet specific requirements, ensuring optimal performance, safety, and longevity.

https://www.jiangyuancables.com/pvc-insulated-sheathed-control-cable/ into the world of custom control cables, exploring their construction, applications, advantages, and key considerations when selecting the right cable for your needs. Additionally, it highlights the importance of partnering with reputable manufacturers and suppliers to ensure the highest quality and reliability.

1. Understanding Custom Control Cables:

1.1 Definition and Basic Construction:

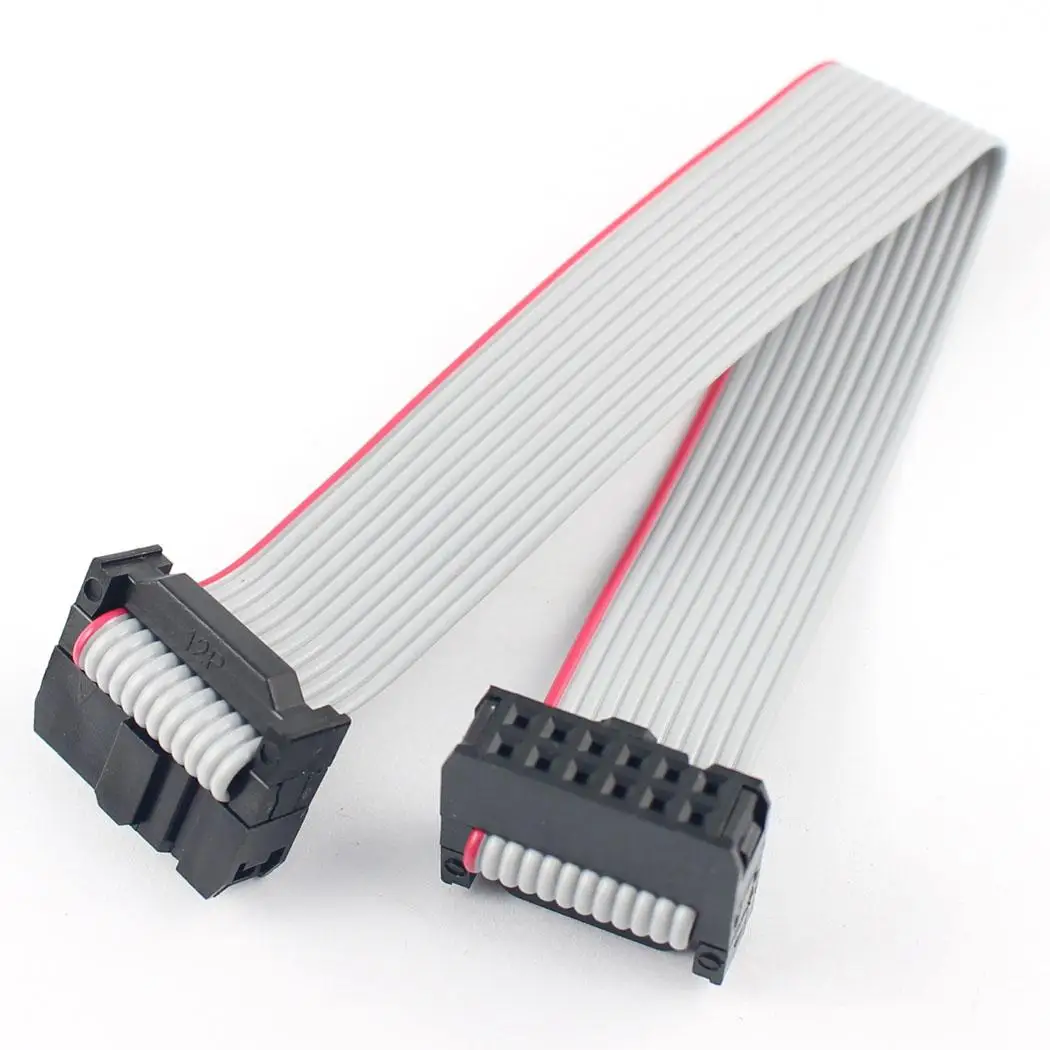

Custom control cables are specialized cables designed to transmit control signals or mechanical forces from one point to another. They are typically composed of multiple conductors, insulation materials, protective jackets, and various additional components, depending on the intended application.

1.2 Types of Custom Control Cables:

There are several types of custom control cables available, each tailored to specific industries and applications. These include:

- Electrical Control Cables: Designed to transmit electrical signals or power with precision and reliability.

- Mechanical Control Cables: Constructed to transmit mechanical forces, such as tension, compression, or torque.

- Hybrid Control Cables: Combining electrical and mechanical elements, these cables are suitable for applications requiring both signal transmission and force transfer.

2. Applications of Custom Control Cables:

2.1 Automotive and Transportation:

Custom control cables play a vital role in the automotive industry, enabling the precise control of various vehicle functions, including throttle, brakes, steering, and transmission. These cables are subjected to high mechanical stresses, temperature variations, and environmental factors, necessitating their durability and reliability.

2.2 Aerospace and Aviation:

In the aerospace sector, custom control cables are essential for controlling critical functions, such as flight surfaces, landing gear, engine controls, and avionics systems. They must withstand extreme temperature variations, high vibration levels, and rigorous safety regulations.

2.3 Robotics and Automation:

Custom control cables are indispensable in robotics and automation, providing precise motion control for robotic arms, gantries, and other automated machinery. These cables must possess excellent flexibility, resistance to repetitive motion, and high precision to ensure accurate and reliable performance.

2.4 Medical and Healthcare:

In medical equipment, custom control cables are utilized for various applications, including surgical robots, imaging devices, patient monitoring systems, and diagnostic equipment. They must adhere to stringent medical standards, ensuring safety, reliability, and compatibility with sensitive electronic components.

2.5 Marine and Offshore:

Custom control cables find extensive use in marine and offshore applications, where they control functions such as navigation systems, winches, propulsion systems, and communication equipment. These cables must withstand harsh marine environments, including exposure to saltwater, extreme temperatures, and mechanical stress.

3. Advantages of Custom Control Cables:

3.1 Tailored Solutions:

Custom control cables offer the advantage of being tailored to specific requirements, ensuring optimal performance and compatibility with the intended application. By working closely with cable manufacturers, engineers can design cables that meet their exact needs, optimizing efficiency and safety.

3.2 Enhanced Durability:

Off-the-shelf cables may not withstand the harsh conditions and mechanical stresses of specialized applications. Custom control cables, however, can be engineered using high-quality materials and advanced manufacturing processes to enhance their durability and longevity.

3.3 Improved Performance:

Custom control cables can be designed to provide enhanced electrical conductivity, mechanical performance, and resistance to environmental factors. This allows for improved signal transmission, reduced energy loss, and increased overall system efficiency.

3.4 Safety and Compliance:

Custom control cables can be manufactured to meet specific safety regulations and industry standards. By partnering with reputable manufacturers, customers can ensure that their cables comply with the necessary certifications and requirements, reducing the risk of accidents and system failures.

4. Key Considerations When Selecting Custom Control Cables:

4.1 Application Requirements:

Understanding the specific requirements of the intended application is crucial when selecting custom control cables. https://www.jiangyuancables.com/flame-retardant-fire-resistant-and-low-smoke-halogen-free-sheathed-power-cables/ as temperature range, flexibility, chemical resistance, and mechanical stress should be carefully considered to ensure optimal performance and longevity.

4.2 Material Selection:

Choosing the right materials for custom control cables is essential. Factors such as conductor materials, insulation materials, jacketing materials, and shielding options must be carefully evaluated to ensure compatibility with the application's demands.

4.3 Customization Capabilities:

Working with a reputable cable manufacturer that offers a wide range of customization options is crucial. This ensures that the cables can be tailored to specific requirements, including length, connectors, color-coding, and labeling.

4.4 Quality and Reliability:

Partnering with a trusted manufacturer with a proven track record of delivering high-quality custom control cables is vital. This helps guarantee the reliability, performance, and longevity of the cables, reducing the risk of downtime, accidents, or costly repairs.

Power cable for robotics :

Custom control cables have revolutionized numerous industries by providing tailored solutions for precise control and efficient operation. Whether in automotive, aerospace, robotics, medical, or marine applications, these cables offer the flexibility, durability, and performance required for optimal system functionality. By understanding the specific requirements and partnering with reputable manufacturers, businesses can harness the full potential of custom control cables, ensuring enhanced safety, efficiency, and performance in their operations.